Focus on R&D prototyping, batch SMT patching and post-soldering, assembly, and testing one-stop services. The management team has an average of 12 to 15 years of experience in the EMS industry. It has 14 composite SMT production lines, imported placement machines and AOI/SPI/XRAY/intelligent testers to ensure quality. The factory provides full BOM material supply.

SMT patch factory is located in Zhejiang

Technology small and medium-sized enterprises

Patch proofing starts in one piece

7 high-speed patch lines/1 proofing line/2 plug-in lines/2 finished product assembly lines

An average of more than 15 years of experience in management

Team authority

Certified quality is traceable

Fast delivery, on time delivery

Components in stock warehouse, minimum order of 1 piece

Whatever you need, we can deliver it within 24 hours

TPS quality control system, quality assurance

Diversified cooperation methods such as contracting work and materials, processing with supplied materials, etc.

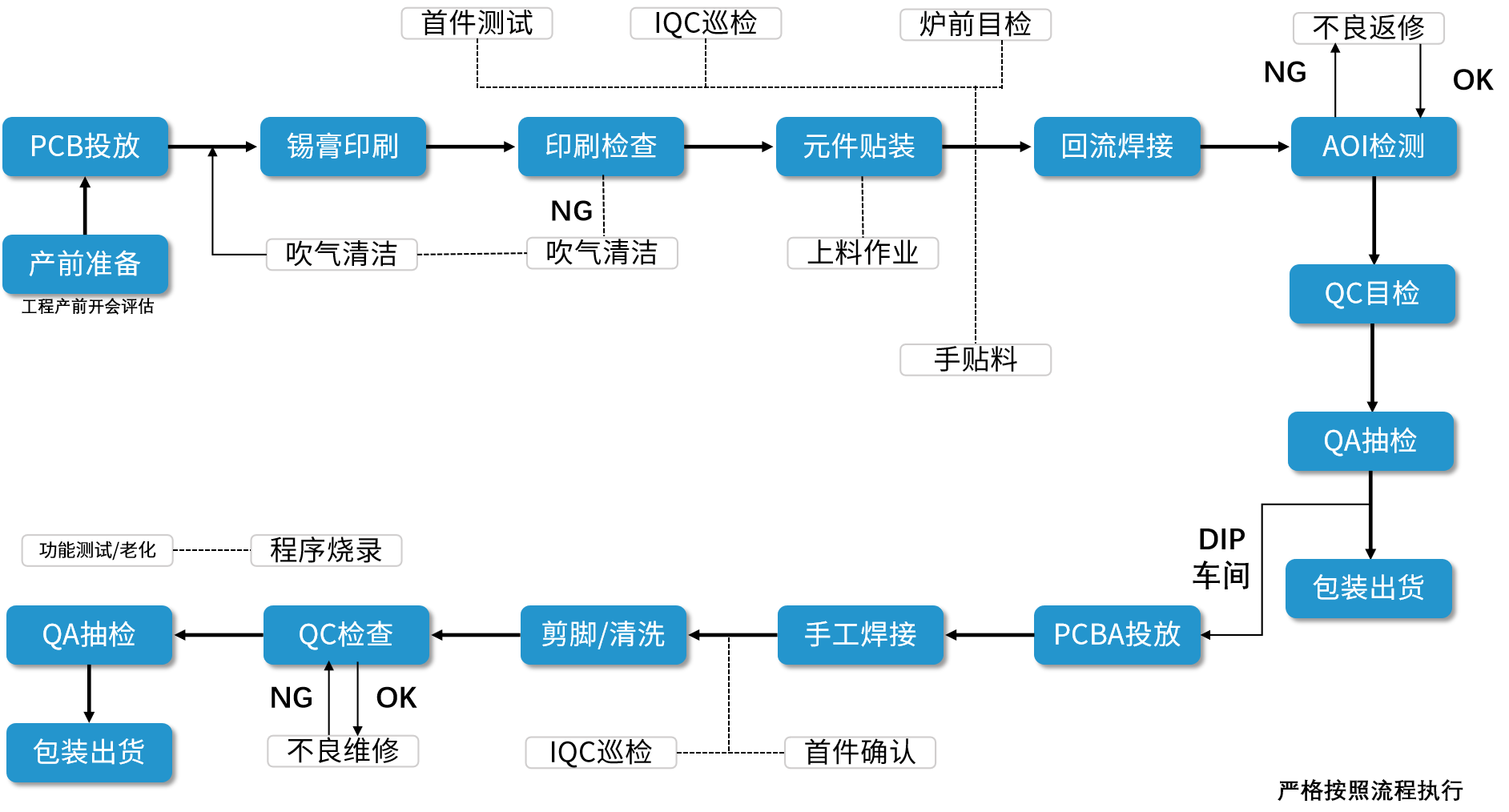

General process flow for assembly and test workshops

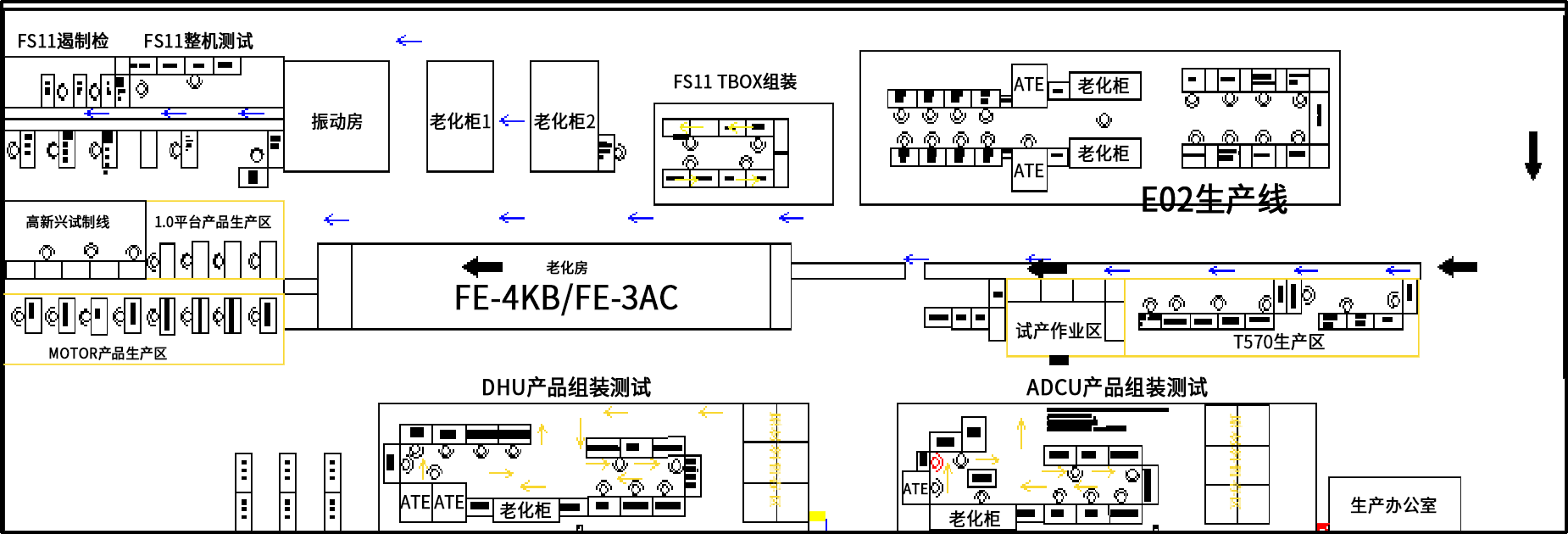

Overall capacity of the assembly and test shop

IPQC random inspection throughout the process

Zhejiang Itronsvs Technology Service Co., Ltd.

Tel:+86-021-51281218

Fax:+86-021-51281218

Room 602, Building B, Hongqiao Green Valley Plaza, No. 588 Shenchang Road, Minhang District, Shanghai

Room 702, Building A4, Optics Valley Financial Port, No. 77 Guanggu Avenue, Jiangxia District, Wuhan City

Building 3, Jinghua Dream Space, No. 350, Jinghua Road, High-tech Zone, Ningbo City, Zhejiang Province

No. 988, Yide Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province (Product Manufacturing Base)

E-mail:sales@itronsvs.com

Contact person: Mr. Fu +86-17316351526